| Brazilian Plastics News |

Arburg highlights participation at Brasilplast 2011.

Representing this series, an Allrounder 720 H with a clamping force of 3,200 kN and a size 1300 injection unit produced flip-top caps for cosmetic tubes. Thanks to its high injection speeds, this high-performance hybrid machine, which features hydraulic accumulator technology, is predestined for packaging sector applications. It produced 24 screw caps with a diameter of 40 millimetres in a cycle time of 11.8 seconds. The throughput was 45.6 kilograms per hour. Furthermore, Arburg exhibited a compact system built around an Allrounder 320 Golden Edition with a clamping force of 500 kN. A complete toy buggy was produced on the hydraulic injection moulding machine in a cycle time of 20 seconds, whereby the wheels, chassis and roof were injected simultaneously. The sprues were removed by the new electric Integralpicker V from Arburg, which is equipped with three servo axes, enabling short set-up and cycle times. “In Brazil, the good price/performance ratio of this machine series ‘Made in Germany’ is highly valued,” adds Kai Wender. “Thanks to its repeat accuracy, the machine is very sought after and represents an ideal entry-level solution for automated moulded part production.” Source: Arburg |

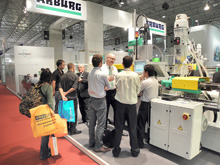

May, 31,2011 - For the Arburg subsidiary in São Paulo, Brasilplast was the most important public appearance in Latin America this year. Numerous trade visitors, particularly from the booming packaging industry, showed interest in Arburg´s injection moulding machines. “The largest plastics trade fair in Latin America was a resounding success for us,” said Kai Wender, Managing Director of Arburg’s Brazilian subsidiary. “The cosmetics and packaging sectors are currently experiencing high growth. We had excellent discussions with trade visitors, particularly from these markets. The interest in our hybrid Hidrive series machines was especially high.”

May, 31,2011 - For the Arburg subsidiary in São Paulo, Brasilplast was the most important public appearance in Latin America this year. Numerous trade visitors, particularly from the booming packaging industry, showed interest in Arburg´s injection moulding machines. “The largest plastics trade fair in Latin America was a resounding success for us,” said Kai Wender, Managing Director of Arburg’s Brazilian subsidiary. “The cosmetics and packaging sectors are currently experiencing high growth. We had excellent discussions with trade visitors, particularly from these markets. The interest in our hybrid Hidrive series machines was especially high.”