| World Plastics News |

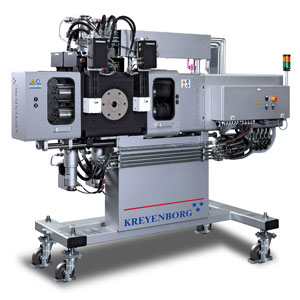

Recycler uses Kreyenborg´s V-Type screen changer without interruption for more than three yearsIn a recycling plant with strand pelletizing, the patented Kreyenborg´s V-type screen changer with integrated self-cleaning function of the screens operates without signs of fatigue

April 22, 2013 - On his production line, a Kreyenborg´s client mainly processes film remnants from PS and PP which contain a high level of contamination. The system was installed over three years ago and continues to perform without error. Despite the high mechanical demands on the system technology, there are no signs of fatigue after more than 51,000 backflush cycles. One cycle comprises the flushing of all four screen cavities, of which there are always at least three in production (Kreyenborg’s patented 75% technology). An overhaul due to rework or wear of the seals is not necessary when using a KREYENBORG piston screen changer because there is no leakage. The screen changer makes more than one hundred backflush cycles with the same screen pack. Then the screens are changed for security reasons in order to avoid fatigue of the mesh. The purpose of these preventive measures is to prevent the bypass of dirt particles around the boundary edge of the screen packs. If and when the screens need to be changed, the replacement of the screen packs is very simple. The V-type easily proves its process stability in a strand pelletizing line. Strand breaks are things of the past when using the V-type, as the constant pressure of this machine type offers unequalled opportunities. In recycling applications for medium to high viscosity materials in which economic filtration is required, Kreyenborg claims that its V-type technology provides a robust and durable solution for a variety of requirements, besides offering a very short payback time. Source: Kreyenborg

|