| World Plastics News |

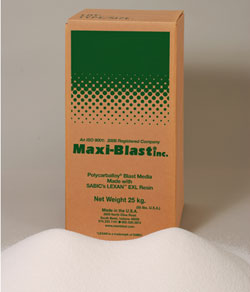

Maxi-Blast Low Temperature Blasting Media Uses SABIC’s Polycarbonate Copolymer Formulation

June 26, 2013 - Collaborating closely with SABIC, Maxi-Blast, Inc., developed a new blasting media solution that maintains efficiency in cryogenic environments for longer periods of time. This is important as the cryogenic deflashing process is being used more often, with the rapid growth in parts consolidation in the auto industry and miniaturization of devices in the healthcare industry. As these markets grow, there is a greater need for a polycarbonate blasting media product that can both withstand the impact of the process without sacrificing performance in cryogenic environments, over extended periods of time. By using SABIC’s LEXAN™ EXL resin, a Polycarbonate Copolymer formulation, Maxi-Blast is able to offer a more valuable blasting media solution to its customers as their industry continues to evolve and grow. “SABIC’s work with Maxi-Blast is an example of our commitment to working collaboratively with our customers to identify new solutions from our broad portfolio that can help propel industries forward, adding value, and helping make them more efficient and productive,” said Nitin Apte, General Manager, High Performance products for SABIC. “The ductility and low temperature impact properties of LEXAN™ EXL resin enhance its longevity and effectiveness, helping deliver enhanced value for customers.” Cryogenic plastic media blasting is beginning to replace traditional methods used for deflashing. In addition to being less abrasive than traditional deflashing media, it is a cost-effective solution, as it offers a better quality finish with shorter cleaning times and it allows the customer to automate the process and recycle the media used. By upgrading with SABIC’s LEXAN EXL resin, Maxi-Blast is able to offer its customers an alternative to the standard polycarbonate. SABIC claims that hrough the use of the proprietary siloxane copolymer technology, LEXAN EXL resin demonstrates enhanced performance under certain conditions in areas such as low-temperature impact strength and cold-temperature ductility. The company also says that the resin retains ductility properties in temperatures as low as -60ºC (-76ºF) and provides better chemical resistance and improved hydro stability when compared to standard PC. “LEXAN EXL resin has provided us with a competitive advantage over general purpose polycarbonate resins by helping us to make our low temperature blasting media better able to withstand cryogenic environments,” said Robert Donaldson, Vice President of Manufacturing at Maxi-Blast, Inc. “The tagline for the Maxi-Blast’s blasting media is ‘It Keeps Its Edge,’ which means that the product maintains a high level of performance even after repeated uses. We are excited to offer a cryogenic blasting media product that remains efficient even in extreme cold temperatures.” Maxi-Blast’s low temperature blasting media made with SABIC’s LEXAN EXL resin can be used in any industry that utilizes intricate, high-performing parts, that require cryogenic deflashing. Source: SABIC |