| Plastics News |

K 2016: Wobbling at the LPKF booth - Welding large components with variable seam widths

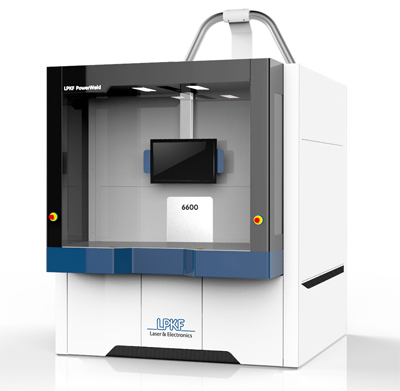

LPKF is presenting a brand new technology on booth E04 in Hall 11 at K show 2016. "Wobbling" enables the LPKF PowerWeld3D 8000 to join large components of up to 100 cm x 70 cm with welds of be-tween one and five millimeter width. It can also handle height differences. "In the automotive industry, more and more components are being manufactured with lightweight plastics. The PowerWeld3D 8000 by LPKF is a system with integrated melt travel monitoring and very short process times". LPKF CEO Lars Ederleh is pleased with the new technology because it considerably extends the range of transmission laser welding. Also at the booth is the LPKF PowerWeld 6600, the leading stand-alone laser welding system. It features the company's new design and many improved com-ponents. Examples include the waiving of compressed air connections thanks to servo-clamping technology, a soft PLC helps raise flexibility and future viability while the modular design delivers a low-cost production unit offering high pro-ductivity. The software developers from Fürth/Germany have also come up with another innovation. The LPKF CAM software ProSeT 3D works autonomously to suggest welding paths based on CAD data. An integrated editor is used to make manual adjustments to waypoints and welding parameters. This system quickly produces welding processes from component layouts – in only minutes. The laser welding system runs LPKF WeldPro software. When in operator mode only that produc-tion data and those commands necessary for production are available, while de-velopers have access to all process data and can even modify individual parameters. Both welding systems and the software will be showcased at K from October 19 to October 26, 2016 at LPKF booth E04 in Hall 11. LPKF Laser & Electronics AG manufactures machines and laser systems used in electronics fabrication, medical technology, the automotive sector, and the production of solar cells. Around 20 percent of the workforce is engaged in research and development. Source: LPKF

|