| World Plastics News |

Engel presents online process control to ensure consistent quality of injection molded parts

Intelligent online process control

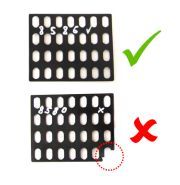

The widely used monitoring of individual screw positions only supplies information on the quality moulded parts are expected to have under certain conditions. To optimise process consistency, ENGEL AUSTRIA has therefore gone one step further. iQ weight control, for which ENGEL has applied for a patent, analyses the pressure profile at screw positions in real time during the injection process and compares the measured values with a reference cycle online. The system then uses this comparison to calculate a new set of highly significant process parameters which allow changes in melt volume and material viscosity – the two most important factors when it comes to the quality of moulded parts – to be detected immediately. If there are deviations from the set values, the relevant process parameters will be readjusted automatically. No extra work for machine operators iQ weight control is integrated into the CC 200 control unit of ENGEL injection moulding machines. As the system automatically analyses and controls the process in real time, changes are counterbalanced before rejects can be produced. The software also reduces the amount of work for the machine operator. ENGEL AUSTRIA will demonstrate the potential of its new software live at Fakuma 2012, which takes place between 16th and 20th October in Friedrichshafen. The company will use a number of demanding application examples to do this. Meanwhile, iQ weight control has already passed its practical test. In its first few applications, the system has guaranteed moulded parts of a consistently high quality, and has also increased the process capability index (Cpk value) by up to 30%. Source: Engel

|

July, 27, 2012 - Producing moulded parts of a consistently high quality shot by shot is the aim. Simply using a precise injection moulding machine will not achieve this, however. Minor changes in ambient conditions or in raw materials and wear and tear suffered by the mould have an affect too and can mean that parameters need to be readjusted. iQ weight control detects these changes automatically and compensates for them in the same shot.

iQ weight control guarantees moulded parts of a consistent quality.

July, 27, 2012 - Producing moulded parts of a consistently high quality shot by shot is the aim. Simply using a precise injection moulding machine will not achieve this, however. Minor changes in ambient conditions or in raw materials and wear and tear suffered by the mould have an affect too and can mean that parameters need to be readjusted. iQ weight control detects these changes automatically and compensates for them in the same shot.

iQ weight control guarantees moulded parts of a consistent quality.