| World Plastics News |

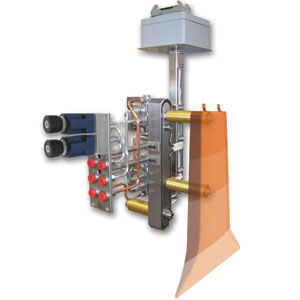

INCOE® Launches New Solutions in Hot Runner Systems Technology.April, 02, 2012 - INCOE® Corporation announced today the introduction of the SoftGate® hot runner valve pin velocity control to global markets. SoftGate®, initially introduced in Europe during K2010, has performed exceedingly well in numerous challenging applications. In those applications, it has successfully improved part and surface quality.

The SoftGate® technology approach precisely operates the hydraulic valve pin actuation at varying intervals to ensure exact, repeatable filling; part after part. The technology consists of a control module in the hydraulic unit and a velocity calibration unit. Combined, the molder now can have improved part appearance and structure with the ability to record the Valve-Gate pin metering that produces the best melt delivery results. SoftGate® also offers simplified and effective operation and ease of maintenance. For added value, the technology has been designed to retrofit onto existing INCOE® hydraulic valve gate systems, allowing molders to take advantage of SoftGate® without the requirement of purchasing a completely new system.

NEW Edge Gate System Technology

INCOE® also announced the introduction a new Edge Gate nozzle design that simplifies integration and maintenance. The new design has bee added to the proven Direct-Flo™ Gold series of hot runners and provides exceptional thermal control and sustainable part geometry in applications requiring a side entry gate location. Example applications include medical vials, syringes and pipettes. Edge Gate system features include: • Split Mold Insert Design • Simplified Assembly • Variable Nozzles Lengths • Profiled and Integrated Heater • Quick Disconnect Wiring • Thermal Tip Performance Variable nozzle lengths from 80mm to 120mm can be specified to the exact dimension required providing complete design flexibility. The dual heater design ensures processing reliability, and is integrated into the nozzle body and gating area. The heater is profiled, applying heat where needed with thermocouple location placed precisely near the gate for optimized thermal control. The TIR results demonstrate the improved part geometry realized when using the new design. Edge Gate nozzles are available in three configurations that allow for 1-2, 1-4 or 1-8 thermal tip gate locations around the circular nozzle head. Tips are coated for added durability and performance and can utilize our exclusive Opti-Flo® rheologically balanced manifolds for enhanced part quality.

NEW Valve Gate Tip Designed for Fast Color Change Applications

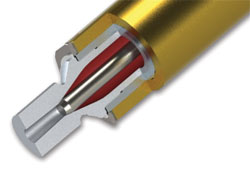

In numerous applications ( i.e. Automotive Interiors), the new tip design has provided excellent color change results in a shorter period of time with substantially improved part quality. The new VIX is applicable for both pneumatic and hydraulic systems using a tapered valve pin, and is suitable for use with INCOE®’s Unitized and Leak-Proof hot runner valve gate systems Together with the SoftGate® valve pin velocity control introduced at NPE for the first time in North America, INCOE® again demonstrates its commitment to continuous improvements and advances in process control to customers by providing solutions that yield higher productivity with improved part quality. Source: Incoe

|

SoftGate® valve pin velocity control technology resolves process challenges related to conventional hydraulic sequential molding. Poor flow characteristics leading to part inconsistency, flow hesitation lines, or blemish marks are reduced with SoftGate®. The gradual pin actuation, precisely timed as needed for optimized melt flow velocity to the mold cavity, provides a key process control advantage for molders.

SoftGate® valve pin velocity control technology resolves process challenges related to conventional hydraulic sequential molding. Poor flow characteristics leading to part inconsistency, flow hesitation lines, or blemish marks are reduced with SoftGate®. The gradual pin actuation, precisely timed as needed for optimized melt flow velocity to the mold cavity, provides a key process control advantage for molders.

A new Valve Gate Tip featuring the VIX End Cap specifically designed for enhanced and fast color change performance has also been launched. The tip geometry has been optimized for improved flow of material required in color change applications. This design is included in the recently expanded range of over 25 gate styles now available with Direct-Flo™ Gold hot runner systems.

A new Valve Gate Tip featuring the VIX End Cap specifically designed for enhanced and fast color change performance has also been launched. The tip geometry has been optimized for improved flow of material required in color change applications. This design is included in the recently expanded range of over 25 gate styles now available with Direct-Flo™ Gold hot runner systems.