| World Plastics News |

New Technology From Dow and Cannon Improves Energy Efficiency of Household Refrigerators by up to 10 percent.

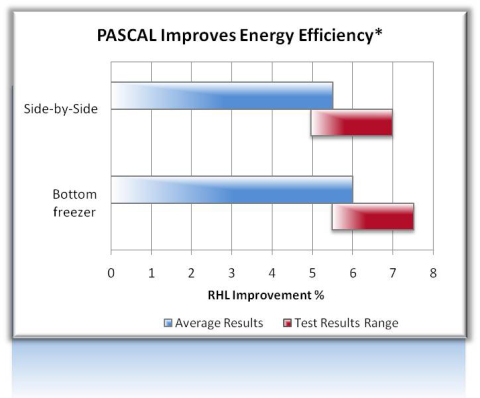

September, 8, 2011 - Dow Polyurethanes, a business within The Dow Chemical Company (NYSE: DOW), in cooperation with Cannon SpA, will officially launch PASCAL™ Technology on September 9 at the Shanghai Summit 2011. PASCAL™, a new polyurethane foam insulation technology that improves energy efficiency of refrigerators and freezers by up to 10 percent, was first featured in household refrigerators and freezers by Haier and is now commercially available to appliance manufacturers. The Shanghai Summit 2011 brings together Italian and Chinese government officials, academic and industry leaders and media to share innovative insights on energy conservation and explore how transformational opportunities can contribute to economic growth and environmental sustainability. The summit is just one of the efforts in the collaboration of the Italian and Chinese governments toward making China a more sustainable country. “This summit is the perfect venue to launch PASCAL,” said Bruno Barbet, Dow Polyurethanes global appliance market leader. “China is one of the largest single-home marketplaces for refrigerators and freezers, as well as a leading global export country, and PASCAL™ Technology can help support the goals of making China’s industrial divisions more sustainable for the future.” Combining a proprietary polyurethane foam specifically formulated for this application, PASCAL™ Technology doubles the efficiency of insulation while continuing to provide thermal conductivity and adhesion—qualities that distinguish polyurethane from alternative types of insulation. PASCAL™ is just one of the innovative solutions spurred by Dow’s commitment to addressing the world’s most critical challenges, including the need to conserve energy. “Governments are setting more stringent mandatory minimum Energy targets, and consumers worldwide are demanding energy efficient appliances,” said Barbet. “With PASCAL, manufacturers may deliver on this demand, while also increasing energy efficiency and output during manufacturing.” PASCAL Technology incorporates vacuum equipment from Cannon SpA, during the insulation process to bypass the deficiencies of standard insulation. The vacuum, paired with a hydrocarbon blowing agent, allows PASCAL polyurethane foam to fit into the small spaces traditional insulation might miss, especially in modern designs, and also mold to the contours of the appliance, reducing the amount of energy lost during consumer use. The resulting system can also decrease the insulation reactivity time from a standard of about five to three minutes. When compared to standard polyurethane insulation processes, PASCAL(TM) Technology out-performs both side-by-side models and bottom freezer models by up to 10%. The test results shown compare PASCAL Technology against standard polyurethane insulation using cyclopentane (CP) blowing agents. "Average Results" represent the average of all tests run on a variety of standard refrigeration models. Results vary per model, and have the potential to realize up to 10% energy efficiency improvement based on a variety of influencing factors as advantages of the Technology continue to be understood. (Graphic: Business Wire) Source: DOW |