| Plastics News |

Sumitomo (SHI) Demag wraps up K 2022 with positive approval

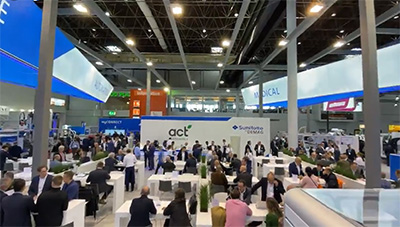

CEO Gerd Liebig evaluates the success of global trade fair, signalling it as being a step towards normality. November 17, 2022 - Gerd Liebig, CEO of Sumitomo (SHI) Demag, concludes that K 2022 was overall a positive exhibition. Although the number of visitors to the world’s leading trade fair dropped by 21 percent compared to 2019, there was an increase in the volume of visitors to the German-Japanese mechanical engineering firm’s booth. Additionally, the CEO claims that the quality of visitors was significantly higher. Liebig explains: "We attribute this increase in quality to our team registering a 20 percent rise in the number of purchase decisions. K 2022 was a big step towards normality. Because visits were scheduled well in advance, it enabled our team to plan and dedicate much more time to supporting the top purchasing decision-makers, all of whom came.“

Sumitomo (SHI) Demag recorded a high proportion of decision-making contacts, while the ratio of the purported ‘running audience’ visiting at the weekend and overall appeared relatively low. "The volume of visitors from Asia - especially China and Russia – meant that it was much more manageable," says the CEO. "Customers are increasingly seeking long term stable partners for the future and are interested in attractive industry solutions," he sums up. Referencing the future status of trade fair events, fears that visitor numbers could further decline, coupled with weak project prospects, was refuted by Liebig. If anything, those that visited were serious decision-makers. Another benefit of this more manageable footfall was the noticeable improvements in transportation logistics, he notes. Sharing his observations of the user industries, Liebig drew another distinction. “Even though economic uncertainties currently dominate, projects in electronics is currently very strong. Also running at a good level are the packaging, medical technology and consumer goods sectors. In contrast, the automotive sector remains rather weak. Despite the dramatic mood and enormous uncertainty, Liebig would not be drawn into the threatening scenario forecast before K 2022 regarding the poor propensity to invest. “Although the mood was somewhat cautious, there are new projects still out there,“ he affirms The effect on trade fair events feared by the resurgent corona pandemic were also absent. “The number of infections was manageable - for our stand staff it was around four percent," Liebig reports. With daily testing, the company had the situation under full control. Another special highlight at K 2022 was handing over the company’s 80,000th fully-electric IntElect injection moulding machine to Tyco Electronics. A partnership previously characterised by ups and downs, all consistently resolved and viewed as the best learning experience, the now very satisfied customer accepted its new machine in the amiable atmosphere of the show, says the CEO. Developments highlighted at K 2022: PAC-E: A packaging world premiere. Featuring low energy consumption and cleanliness, PAC-E is the newest all-electric, high-speed innovation from Sumitomo (SHI) Demag. Engineered specifically for manufacturers of beverage closures and thin walled packaging applications Automation: Presenting the next phase of the Sumitomo. Machine (SAM) robotics and automation journey, including the integration of a standardised SAM-C “handle&box” robot with an IntElect 75; a new large work envelop 6-axis SAM-S (Scara) system with special kinematics; plus the unveiling of SAMControl Eco-Packaging: Introducing MuCell with VDMA at the Circular Economy Forum (outdoor pavilion). Featuring an IntElectS 180 machine integrated with advanced IML, producing hinged flip top lids for baby milk powder containers. Including an aesthetically pleasing and patented 3D visual effect Smart Solutions: New digital tool myAssist for process transparency. Securely recording time series data and analysing process parameters to mark the next phase forward in the journey towards digital validation and the digital product pass Sustainability influencers showcased CO2-neutral e-mobility manufacturing collaboration. Presenting functionality and decorative manufacturing techniques, to produce a ‘smart’ EV-charging wallbox on an IntElect 220 using a multi-functional 5-axis linear robot SD 22x Showcasing LSR processing stability, sustainability and synergy, revealing OPC-UA compatible interface to support interoperability between the moulding machine and LSR dosing systems and support data contextualisation. This IntElect LSR package also unveiled inaugural tooling partnership with ELMET, plus seamless automation with the new 6-axis SAM-S hybrid robot comprising Scara mechanics and linear robots Latest advances in ultra-short forming medical processing, including high speed extraction. Deployment of the hybrid high-speed El-Exis SP 420 optimises material use and cools the mould faster. Resulting in the release and analysis of 48 high quality medication dispensing cups in under three seconds Sumitomo (SHI) Demag As a specialist for injection moulding machines for plastics processing, Sumitomo (SHI) Demag and its Japanese parent company are present in all major plastics markets. The global development and production network of Sumitomo Heavy Industries and Sumitomo (SHI) Demag is comprised of four facilities in Japan, Germany and China with more than 3,100 employees. The product portfolio includes all-electric, hydraulic and hybrid injection moulding machines with clamping forces of between 500 and 15.000 kN. With more than 162,000 installed machines, Sumitomo (SHI) Demag is present in important global markets and ranks among the largest manufacturers of injection moulding machines in the world. At Sumitomo’s headquarters in Chiba, Japan, the company manufactures machines with clamping forces in the small to medium range. Nearly 95 % of all delivered machines are equipped with an all-electric drive concept. Sumitomo (SHI) Demag’s German facilities in Schwaig and Wiehe produce the Systec Servo range with hybrid drive as well as the El-Exis SP and Systec SP range of high-speed, high-performance machines. The all-electric IntElect range for international customers is also being produced in Germany. As early as 1998, Sumitomo (SHI) Demag set up its first production site in Ningbo/China. In 2015, the Chinese subsidiary Demag Plastics Machinery (Ningbo) Co., Ltd. installed a new facility with a 13,000 m² floor space. It is earmarked for the production of the Systec C range with clamping forces of between 500 and 10,000 kN for the Asian market. In addition to injection moulding machines, Sumitomo (SHI) Demag offers customised and standardised systems for the part handling automation, technical and process solutions for special applications, tailored services and service concepts as well as a range of financial options to support investment in injection moulding machines. Source: Sumitomo (SHI) Demag

|

Liebig (photo) cites rapidly escalating energy prices for the significant interest shown towards all-electric injection moulding machines, along with the comprehensive display of Sumitomo (SHI) Demag exhibits, as being the rationale for these developments. “The introduction of the new all-electric high-speed injection moulding machine PAC-E was a big attraction, playing to our strengths. Additionally, visitors showed great interest in our in-house automation SAM robotic series, plus smart solutions myConnect and myAssist,” states Liebig.

Liebig (photo) cites rapidly escalating energy prices for the significant interest shown towards all-electric injection moulding machines, along with the comprehensive display of Sumitomo (SHI) Demag exhibits, as being the rationale for these developments. “The introduction of the new all-electric high-speed injection moulding machine PAC-E was a big attraction, playing to our strengths. Additionally, visitors showed great interest in our in-house automation SAM robotic series, plus smart solutions myConnect and myAssist,” states Liebig.