| Plastics News |

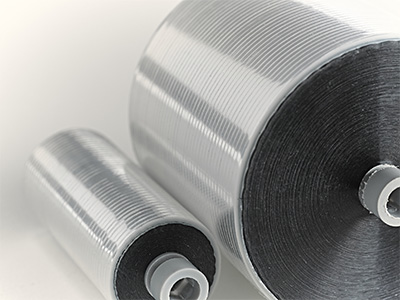

Borealis and Topas currently developing new class of engineering material for film capacitor applications

September, 23, 2021 - Borealis, a leading provider of polyolefins solutions, and Topas Advanced Polymers, a leading producer and marketer of cyclic olefin copolymers (COC), have started collaboration on the development of a new class of engineering materials for capacitor film applications. According to Borealis and Topas, the new materials will bridge the current performance gap between standard polymers and high-end plastics. The companies claim that by enabling significantly higher film capacitor temperature resistance at lower cost, this new material will be a step change in power transformation and transmission: it will make traction inverters for electric mobility more energy efficient at higher temperatures; and it will allow inverters to more efficiently transform power from renewable sources like wind or solar. Once commercially available, the first applications of this material class will be in traction inverters for electric mobility and inverters for solar and wind. It has the potential to accelerate the green-energy transition towards renewables and contribute to achieving the greater goals of the European Green Deal, the companies say. Combining two worlds: Borealis PP capacitor film and Topas COC Borealis and Topas Advanced Polymers are drawing on their respective expertise and track record to develop a new class of engineering material for thin, highly heat-resistant capacitor film applications. According to the companies, the EPN (ethylene-propylene-norbornene) material now in development will increase the temperature resistance of film capacitors significantly – by 20°C to 35°C – in comparison to capacitors made of standard polymers. This will close the current gap between conventional polymers and costly high temperature plastics by enabling the use of polymeric film capacitors at endurance temperatures of up to 140°C, the companies claim. Combining the highest electrical purity with superior homogeneity, the new material should be designed for the production of ultra-thin and highly consistent films in the range of 2 to 6 microns gauge. Provided the appropriate processing parameters are in place, the new material is targeted to be suitable for use on BOPP (biaxially oriented polypropylene) film processing machines. Higher-performance film capacitors are a crucial element in all power transformation systems that bring about the green-energy transition in a cost-efficient way. The new material class now being jointly developed by Borealis and Topas Advanced Polymers will be used in electric mobility units, particularly when higher endurance temperature resistance and consistent frequency control is essential, such as in electric vehicles and high-speed trains. It will also help address one of the major challenges of the green-energy transition by enabling the large-scale provision of more cost and energy-efficient capacitors for inverters that transform HVDC power generated from renewable sources on and offshore, such as from windfarms or photovoltaic arrays, into HVAC and back – with minimal energy loss. “For conventional energy to be replaced by power from renewable sources, energy transformation and transmission must become more efficient and affordable. Meeting this challenge is the goal of our co-operation with Topas Advanced Polymers,” says Anton Wolfsberger, Director Strategic Polyolefins Business Projects at Borealis. “In the near future, this step-change material class will benefit both the power industry value chain as well as end consumers. We are proud to be working with Topas to enable green energy at a greater scale and to contribute to achieving the European Green Deal’s ambitious energy aims.” “It is exciting to develop a solution that will become a cornerstone for the transition of the energy supply system. We had been intrigued by the potential, which we plan to tap by joining forces with Borealis’ material expertise in polyolefins and specific market know-how. When we started this development it became obvious rather quickly, that this collaboration is the perfect match to deliver the best product with exceptional performance for this demanding application,” commented Keisuke Goto, GM Corporate Strategy Polyplastics CO., Ltd as the main shareholder of Topas business. Topas Advanced Polymers is the world’s leading maker of COC (cyclic olefin copolymer), a glass-clear and extremely pure plastic for healthcare, optics, packaging, and electronics applications. It is used in a range of applications such as in insulin delivery, food contact films, tablet and smartphone components. Topas Advanced Polymers is a business of Polyplastics Co., Ltd., a global leader in the development and production of engineering thermoplastic solutions. Along with COC, the company’s product portfolio includes POM, PPS, PBT, and LCP plastics. The company has the largest global market share of POM, LCP and COC. With more than 50 years of experience, the company is backed by a global network of R&D, production, and sales resources. Topas is a registered trademark of Topas Advanced Polymers GmbH in Germany, the United States, and other countries for its family of cyclic olefin copolymer resins. Source : Borealis |