| Plastics News |

Maguire integrates new features into Ultra dryer touchscreen controller

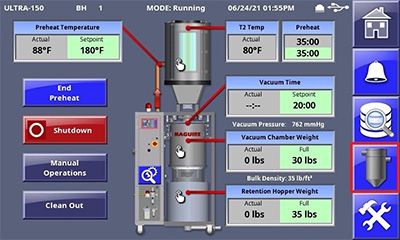

July 22, 2021 - Maguire has made its Ultra dryer touchscreen controller more feature rich by integrating the Company’s FlexBus Lite software into the platform’s powerful Arm Cortex microprocessor. According to Maguire, FlexBus Lite, a standard feature on all touchscreen blender controls, is now integrated into the Ultra dryer touchscreen controls, allowing users complete pump and receiver control in a cell, in a user friendly and straightforward control system. Maguire sayts that its FlexBus Lite features an Intuitive receiver and pump control – with features typically only found on larger central system controls. It allows control of 1 vacuum pump and full system functionality control of up to 10 materials receivers. The Icon based touchscreen shows each of the receiver’s activity in real time whether it is calling for material, receiving material into it, or showing material discharging. The pump and receiver settings can be easily adjusted in real time by the operator, the company claims. “With the dryer, vacuum chamber and material retention hopper on load cells – you are able to completely regulate the drying rate to the process rate. This allows the operator to program a shutdown to any specific day and time,” said Frank Kavanagh, vice president of sales and marketing. “The control system then monitors the rate so that the loader will stop calling for material and the dryer will be empty. With the control system monitoring the rate, this makes material changes even easier.” Maguire claims that FlexBus Lite on the Ultra dryer offers full feature conveying control with several advantages:

Headquartered in Aston, Pennsylvania, USA, Maguire manufactures gravimetric blenders and feeders, volumetric feeders, Ultra low energy dryers, conveying systems, extrusion control systems, loss in weight extrusion control, and related auxiliaries. Founded in 1977, Maguire Products operates seven manufacturing facilities in Aston, with seven international subsidiaries that service an extensive network of distributors globally. Source : Maguire |