| Plastics News |

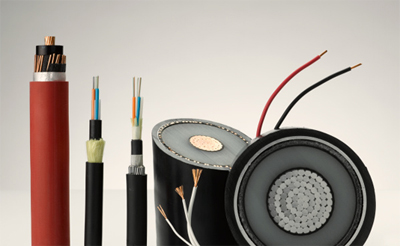

Borealis and Borouge launch new flame-retardant solution for low voltage cables used in demanding environments

April, 16, 2020 - Borealis and Borouge are expanding their existing portfolio of flame-retardant (FR) jacketing grades with the launch of FR8101. The companies say that its new, halogen-free solution is based on metal hydrate technology and is intended for the production of low voltage building cables used in highly demanding environments. According to the manufactureres, cable manufacturers can offer an even safer product with better performance while at the same time achieving increased production efficiency by using FR8101. Cables made with FR8101 can minimize flame spread and flaming droplets The new FR8101 is based on a highly flame-retardant metal hydrate technology. In the event of a fire, the material actually releases water to reduce the intensity of the flames. According to Borealis and Borouge, jacketing made with FR8101 is resistant to the flaming droplets which often cause fire to spread within buildings where cables are installed inside walls and roofs. By retaining its shape even in intense heat, FR8101 jacketing stays on the cable, even if the cable is burnt, the companies assure. In fact, depending on the type of construction, FR8101 can even earn the best possible rating of “d0” in the Construction Products Regulation (CPR) Euroclass scale for flaming droplets, the manufacturers say. This highest level of flame retardancy makes it possible for cable industry partners to fulfil the stringent CPR cable standards in Europe when using FR8101, Borealis and Borouge claim. Up until now, cable manufacturers have been bound by certain limitations when using conventional halogen-free flame-retardant (HFFR) cable compounds. For example, material decomposition during the extrusion process can result in lower production speeds and inferior cable performance. Borouge and Borealis say that the use of FR8101 eliminates these issues altogether by allowing cable makers to run production lines at high speeds thanks to the mechanical properties offered by this grade. According to the manufacturers, the new grade is a simple way for processors to fulfill CPR requirements without having to use other FR insulation or bedding, when used in tandem with a crosslinked polyethylene (XLPE) insulation solution provided by Visico™/Ambicat™. This makes for more efficient processing during production, but also lighter cables, and thus easier installation, Borealis and Borouge claim. It also helps raise manufacturers’ own sustainability standards with regard to health and safety. “The launch of FR8101 provides an innovative and more effective solution that addresses important industry challenges,” explains Bart Verheule, Borealis Head of Marketing, Energy. “Borealis and Borouge are committed to bringing energy all around by supplying new ways for our partners to make safer and more sustainable cables. This in turn helps raise standards in health and safety for everyone.” Source: Borealis / Borouge . . |