| Plastics News |

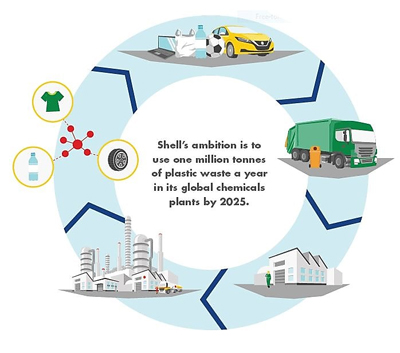

Shell uses plastic waste to produce feedstock through a pyrolisys process

January, 22, 2019 - Shell announced on November, 19 it had successfully made "high-end" chemicals using a liquid feedstock made from plastic waste. The technique, known as pyrolysis, is utilized to chemically break down hard-to-recycle plastics into basic chemicals and advances Shell’s ambition to use one million tonnes of plastic waste a year in its global chemicals plants by 2025. “This makes sense for the environment and our business,” said Thomas Casparie, Executive Vice President of Shell’s global chemicals business. “We want to take waste plastics that are tough to recycle by traditional methods and turn them back into chemicals – creating a circle. These chemicals will meet our customers’ growing demands for high quality and sustainable products.” Atlanta-based Nexus Fuels LLC recently supplied its first cargo of pyrolysis liquid to Shell’s chemical plant in Norco, Louisiana, USA where it was made into chemicals that are the raw materials for everyday items. Shell is working with multiple companies who collect and transform plastic waste in order to scale this solution to industrial and profitable quantities across its chemicals plants - in Asia, Europe and North America. Pyrolysis is a chemical recycling process of heating plastic waste without oxygen such that it breaks down the longer chain polymers into shorter chain materials. These products can then be further processed into chemicals feedstocks or fuels. Pyrolysis can be more effective than the traditional mechanical recycling process of melting as it does not degrade the quality of the final plastic and requires less intensive sorting of the initial waste. Shell is a founding member of the Alliance to End Plastic Waste (AEPW). This not-for-profit organisation is bringing together top minds from across the plastics value chain (chemical and plastic manufacturers, consumer goods companies, retailers, converters and waste management companies) and partnering with the financial community, governments and civil society. The AEPW has committed $1.5 billion over the next five years to help end plastic waste in the environment. Shell is also working with its retail, business fuels and lubricants customers to help reduce, reuse and recycle plastic packaging. Shell manufactures base chemicals - ethylene, propylene and aromatics – using oil and gas as feedstock. The company also make intermediates, such as mono ethylene glycol (MEG), polyols and alpha olefins, and certain performance products, such as polyethylene. Shell’s global chemicals business sells around 18 million metric tons of petrochemicals per year to over 1000 industrial customers. Shell’s integrated refining and chemicals plants are in Asia-Pacific (Singapore), Europe (the Netherlands), and North America (the US Gulf Coast and Canada). The company also operates three major petrochemical facilities in the USA at Deer Park, Texas; Norco and Geismar in Louisiana; and additional chemicals manufacturing in Canada at Scotford and Sarnia. Nexus converts waste plastics into feedstocks, fuels, waxes and other marketable materials. The company says it meets the demand for renewable alternatives at market-driven prices. It is currently operating a commercially-scaled 50-ton/day plant. Clients include companies converting Nexus pyrolysis products back to chemicals and others refining these products into fuels. Nexus claims to be an end-to-end business – not simply a technology - including software, front-end handling, regulatory approvals, training/safety procedures, engineering, logistics and more led by an experienced team and guided by financially-driven metrics. The company says it has already sold over 75,000 gallons of pyrolysis products to a rapidly growing group of global customers. Source: Shell . . |